6 Razões Para Usar Manutenção Preventiva

Descubra como a manutenção preventiva corta custos e prolonga a vida útil dos ativos, mantendo as operações seguras, eficientes e em conformidade.

Keep readingLatest Articles

Artificial Intelligence Assisted Maintenance, The Evolution of Reliability

Much is discussed about different types of maintenance and how they’ve evolved over time. But one thing is crystal clear: technology plays a pivotal role in giving rise to new categories of maintenance. And the freshest example of this phenomenon is Artificial Intelligence Assisted Maintenance. AI has been a hot topic in industrial and manufacturing circles over the past few years. What used to feel remote from the everyday lives of maintenance experts and shop floor professionals has no

Tractian Inc

Sensitive Inspection Routes: Optimizing Industrial Maintenance

One of the most widely used maintenance techniques, sensitive inspection routes consist of using the human senses to assess equipment and component condition. Sensitive inspection relies fully on the inspector’s expertise, and through it, it’s possible to identify a series of faults and serious problems in machines and processes. By hearing, it’s possible to identify irregular noises such as knocking, rattling, and dragging sounds, indicating overloads, loose parts, and excessive vibration, am

Michael Smith

Mechanical Vibrations and Their Role in Asset Monitoring

Let’s say we have a motor, a fan, and a bearing. What do they have in common? Well, aside from each being an asset, they’re linked by the fact that they all generate mechanical vibrations. As many maintenance workers know, many industrial assets emit a spectrum of vibrations – it identifies and distinguishes them from each other. Known as the original spectral signature, it’s generated by different asset components. Because each machine produces this particular signature identifying it, mechan

Tractian Inc

How Yara's Maintenance Became a Reference for Efficiency and Profitability

Yara is the largest fertilizer manufacturer in the world – they have sales in 140 countries across the globe with over 200 warehouses, blending units, and bagging facilities in 60 of those countries. They pioneered the use of nitrogen-based systems in the industry, and continue to lead innovation in the crop nutrition sector. With production sites on six continents, Yara quickly realized they were indispensable. After all, they’re responsible for fertilizing around 80% of the food chain. This r

Tractian Inc

Maintenance Procedures and Their Importance

Procedures, in the broadest sense, are the way something is performed, that is, a technique, process, or method of work. In industrial environments, these tools are widely used in the search for certain patterns of routine tasks and execution. It’s common for people to refer to procedures as work instructions, which they are, but technically there’s a difference. A procedure is a description of the activities involved in the flow of a job. In other words, it’s a macro and standardized script

Billy Cassano

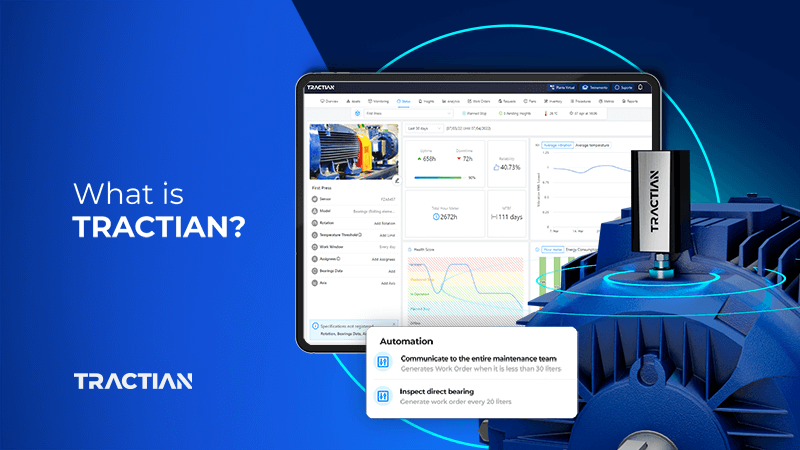

How TRACTIAN Helps Your Maintenance Management

TRACTIAN exists to facilitate and optimize the routine of the professionals who work on the front line of industries, the maintenance managers. Our goal is simple and clear, but understanding how we put it into practice may seem a little more complicated, since our products differ from everything else in the maintenance market today. That is why, today, we bring you a complete manual of all the TRACTIAN solutions so you can understand once and for all who we are, what we do, and how our predi

Alex Vedan

Offline and Online Predictive Maintenance?

You already know that in maintenance management, predictive maintenance is how we call the continuous monitoring of an asset. This methodology is directly related to the prevention of potential failures that can affect the machine’s condition. And to prevent them, monitoring based on data collection is required. There are two methods of asset monitoring in predictive maintenance: offline monitoring and online monitoring. The name may be similar, but they are very different from one another, e

Alex Vedan

TRACTIAN Video Library

Discover our YouTube ChannelComprehensive free materials for your maintenance and reliability

Get free access to materials for increased productivity and an optimized maintenance routine.