MAINTENANCE METRICS

Master Your Maintenance Calculators

Instantly Calculate Key Maintenance Metrics to Optimize Operations and Reduce Downtime.

Instantly Calculate Key Maintenance Metrics to Optimize Operations and Reduce Downtime.

Measure the productivity of your equipment by calculating availability, performance, and quality to identify hidden losses and boost efficiency.

Learn more

Your OEE is

Calculate the average time it takes to repair equipment and restore operations. A key metric to reduce downtime and improve responsiveness.

Learn more

Your MTTR is

Estimate the expected time between failures of your assets to increase reliability and plan proactive maintenance.

Learn more

Your MTBF is

Calculate the average operational time before a non-repairable asset fails. A key metric for improving product design, reliability, and lifecycle planning.

Your MTTF is

Find out how much of your maintenance work is planned vs. reactive. Improve scheduling and reduce emergency repairs.

Learn more

Your PMP is

Determine the frequency of asset failures over time. Essential for risk assessment and reliability-centered maintenance (RCM).

Learn more

Your Failure Rate is

Measure the percentage of time technicians spend on actual hands-on work versus administrative or idle time. Optimize workforce efficiency.

Learn more

Your Wrench Time is

Track maintenance costs relative to asset replacement value. A benchmark to identify cost-saving opportunities and asset performance.

Learn more

Your RAV is

Quantify unexpected equipment outages and their impact on production. Pinpoint areas for reliability improvement.

Learn more

Your Unplanned Downtime is

Get detailed insights on equipment downtime, including frequency and duration, to reduce lost production hours.

Learn more

Your Equipment Downtime is

Get detailed insights on equipment downtime, including frequency and duration, to reduce lost production hours.

Learn more

Your Equipment Availability is

Track adherence to your preventive maintenance schedule. Ensure tasks are completed on time to avoid breakdowns.

Learn more

Your PMC is

Calculate the average maintenance cost per asset over a period. Ideal for budgeting and cost control strategies.

Learn more

Your MMC is

Assess how well your team sticks to the maintenance schedule. Enhance planning accuracy and reduce backlog.

Learn more

Your Schedule Compliance is

Download our ebook for free.

FAQ

Explore all the materials we offer for free to help you grow professionally and elevate your industry expertise.

Ebook

We demystify all maintenance indicators to enhance your management.

Access Material

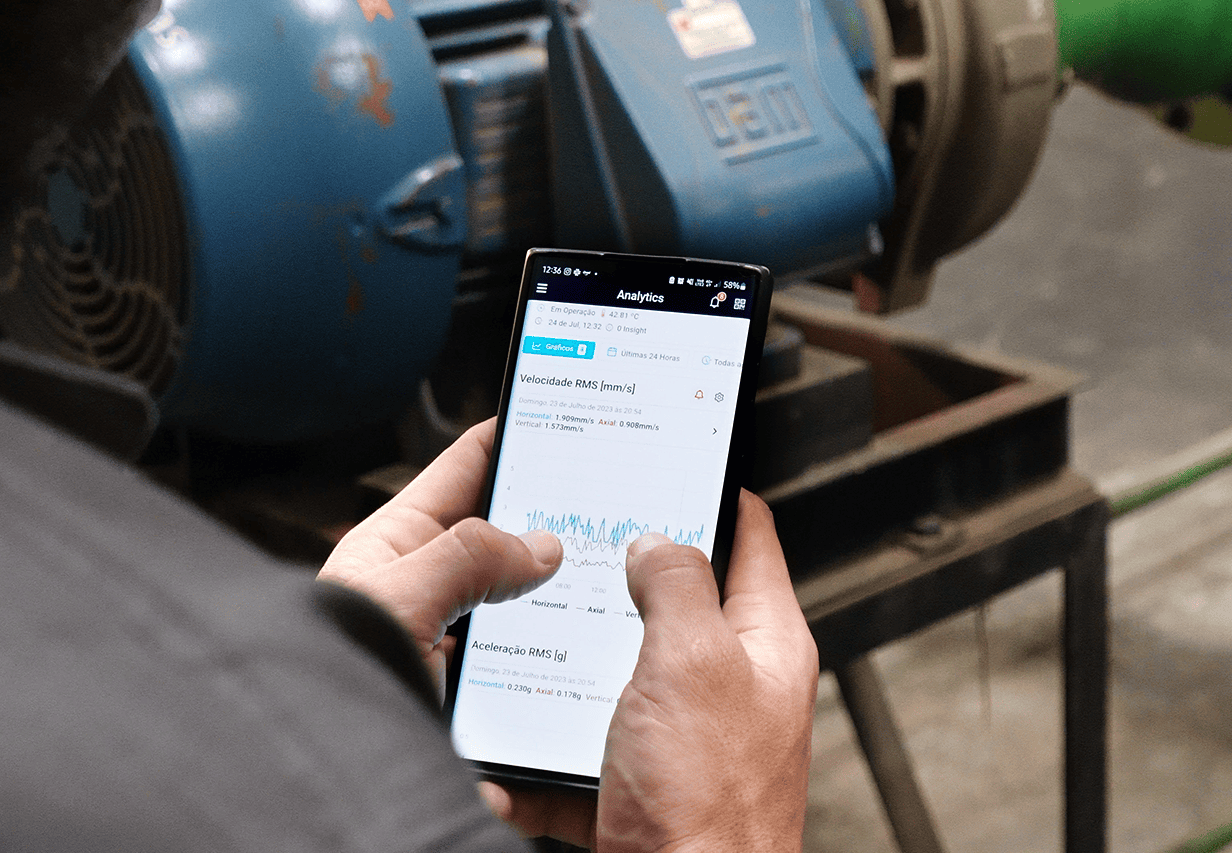

Ebook

Learn how to monitor asset vibration and perform realtime analyses, avoiding downtime and unexpected losses.

Access Material

Ebook

Learn how useful life and failures influence the behavior of your assets.

Access Material