Condition Monitoring System Comparison Guide

Compare five condition-monitoring system types, from basic sensor networks to closed-loop platforms. See how they differ on diagnostics, execution, and maintenance execution.

Updated in feb 20, 2026

Condition Monitoring System Comparison Guide

Compare five condition-monitoring system types, from basic sensor networks to closed-loop platforms. See how they differ on diagnostics, execution, and maintenance execution.

Updated in feb 20, 2026

Ultrasound & Vibration Sensor: Condition Monitoring Playbook

Learn why combining ultrasound and vibration in one continuous monitoring system closes the detection gaps that single-signal, route-based programs leave open.

Updated in feb 19, 2026

How to Choose the Right Vibration Monitoring Device

Every rotating asset in your plant is talking. The question is whether you're listening. A vibration monitoring device translates the mechanical signals from motors, pumps, and gearboxes into data that reveals developing faults, which account for 42% of manufacturing downtime, before they cause unplanned shutdowns. This guide covers how these devices work, the different types available, and what to look for when selecting one that fits your operation. What is a vibration monitoring device A

Updated in feb 09, 2026

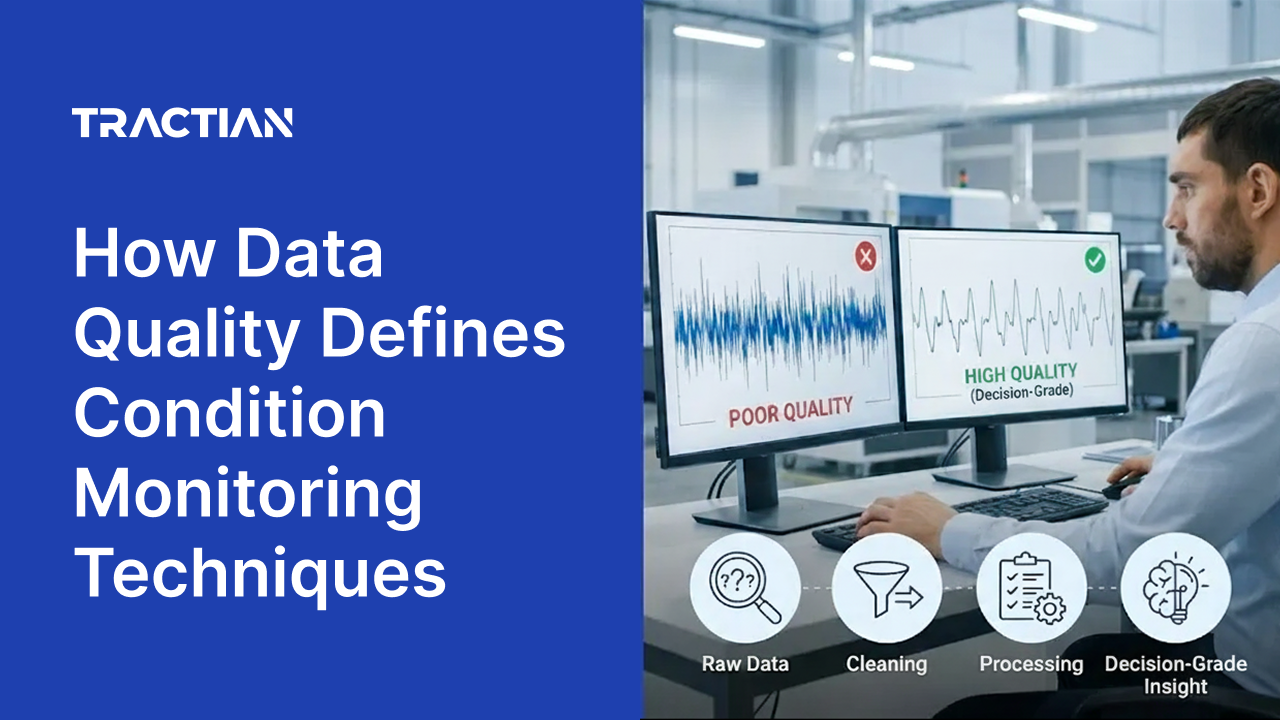

How Data Quality Defines Condition Monitoring Techniques

Condition monitoring techniques succeed or fail based on data quality, not method selection. Learn what decision-grade data requires.

Updated in feb 19, 2026

Why Condition Monitoring Analysis Alone Doesn’t Drive Action

Condition monitoring analysis produces data, but action requires trust, prioritization, and workflow integration. We discuss what bridges that gap.

Updated in feb 07, 2026

From Condition Monitoring Signals to Asset Health Management

Asset health management goes beyond signal monitoring. Learn what decision-grade condition monitoring requires and how to turn data into confident action.

Updated in feb 02, 2026

Why Condition Monitoring Still Fails at Decision Time

Condition monitoring generates data, but data doesn’t make decisions. Learn why most systems fail at decision time and what decision-grade monitoring requires.

Updated in feb 02, 2026

What Is Condition Monitoring? A Modern Definition

Detect equipment failures early with vibration analysis, thermography, and oil monitoring. Build a CbM program that turns real-time data into maintenance action.

Updated in feb 02, 2026